Rotork is a market-leading global provider of mission-critical flow control and instrumentation solutions. Customers rely on Rotork for innovative, high quality and dependable solutions for managing the flow of liquids, gases and powders. Rotork helps customers around the world to improve efficiency, reduce emissions, minimise their environmental impact and assure safety. We operate across three end market focused divisions. These are Oil & Gas, Water & Power, and Chemical, Process & Industrial (CPI). This end market aligned structure means we can build close strategic relationships with our customers and directly meet their needs.

ROMpak electric actuators provide quiet and reliable operation for small ball valves and butterfly valves, as well as dampers and ventilation louvres. They provide local controls, status indication, isolated control circuits, network control compatibility and manual override options together with a wide range of voltages. Part-turn direct drive electric actuators with self-contained, integral local control unit (local/remote, on/off), Continuous position indication at all times, even without power via local mechanical indicator and LEDs, Small, compact and lightweight• Proven reliable design• Manual override for emergency operation ,IP68 (10m / 100 hours)• 12/24 VDC, 110/220 VAC 1-phase and 220/380/440 VAC 3-phase, 50 Hz and 60 Hz

The Rotork Master Station provides the high integrity link from the Distributed Control System (DCS) to the devices in the field. It comes complete with a large touch screen interface to allow operators and engineers to see exactly what is happening to the system and the field devices at any time. A hot standby Rotork Master Station allows for continued availability of the system in the event of a component failure. Host ports allow connection to multiple host systems at the same time with redundant communication links where necessary. In the event of a fault occurring, the changeover to the standby is seamless without loss of data and control.

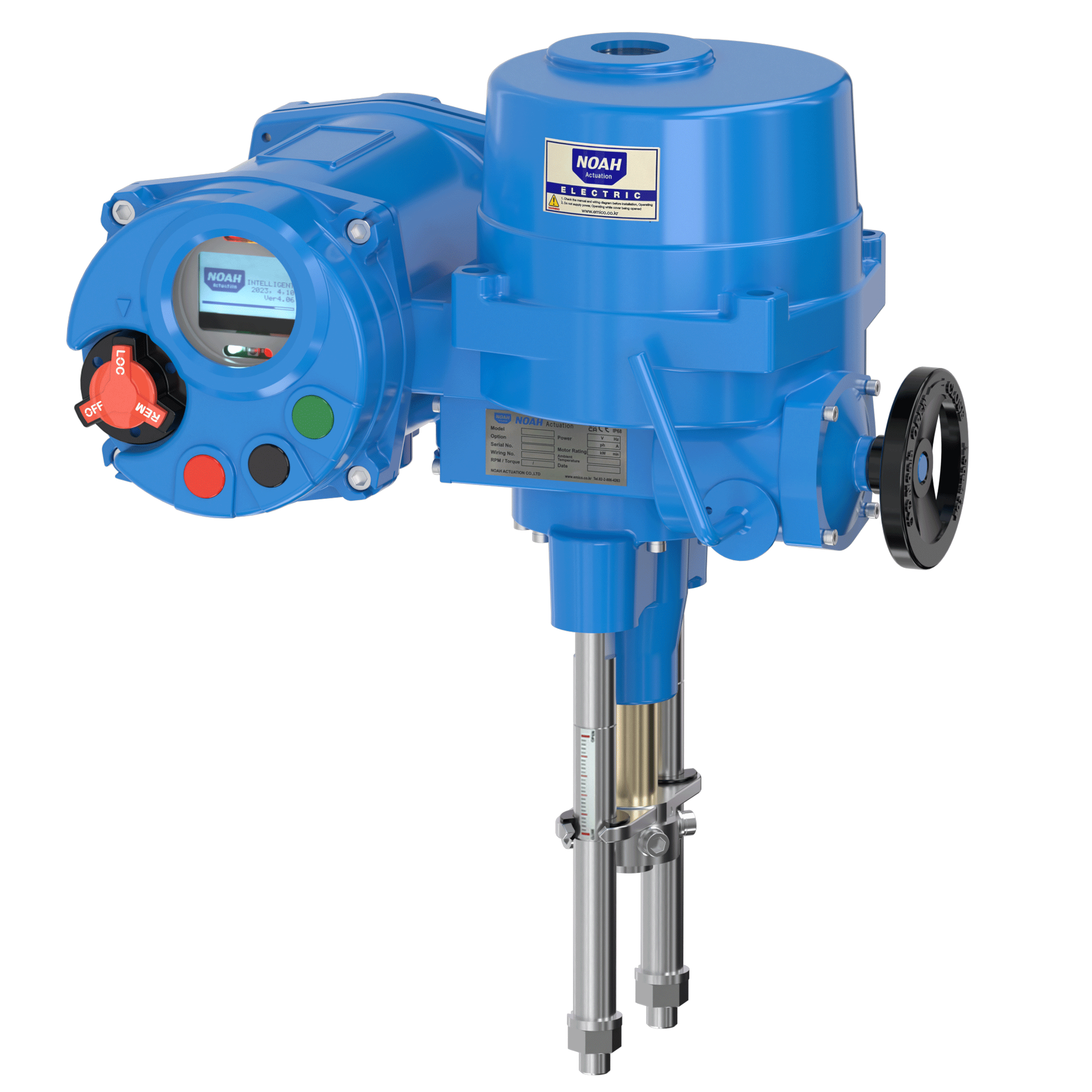

Noah Akt is an advanced electric actuator engineered for the reliable and precise operation of valves and dampers in various industrial applications. With a robust and compact design, Noah Akt offers easy installation, user-friendly local controls, and seamless integration with automation systems. Features include continuous position indication, manual override for emergencies, and high protection class for harsh environments. Its versatility and performance ensure maximum efficiency and operational safety in demanding conditions.

The 242-AB series gearbox is engineered for the most demanding industrial applications, offering exceptionally high torque capacity and extreme durability. Its heavy-duty design enables precise and safe operation of large-diameter or high-pressure valves, even under harsh process conditions. The 242-AB features reinforced bearings, robust gearing, and adaptable interfaces for both manual and motorized actuation.

Soldo limit switch boxes provide robust, reliable position feedback for industrial valves. Designed for harsh environments, Soldo products offer high ingress protection (up to IP67/IP68), easy visual indication, and a wide range of certifications, including ATEX and SIL. Soldo’s compact, modular designs are compatible with all major actuator brands and ensure safe, accurate monitoring and control in on/off or modulating applications.

YTC positioners and limit switch boxes are known for their precise and stable valve control across various process industries. YTC’s smart and pneumatic positioners ensure accurate modulation, fast response, and compatibility with most actuator types. Featuring easy calibration, reliable feedback, and wide certification options, YTC solutions help optimize performance and safety in automated valve systems.

Schischek offers explosion-proof electric actuators and sensors designed for HVAC and industrial automation in hazardous areas. With ATEX and IECEx certifications, Schischek actuators provide safe, reliable control of dampers, valves, and other equipment in zones with explosive gases or dust. Their modular design, easy integration, and robust construction ensure precise operation and long service life even under extreme conditions.